Address: 1340 12th St. Oakland, CA 94607

SERVING THE BAY AREA SINCE 1966

Blog Post

SHRINK WRAPPING YOUR SCAFFOLD: A GUIDE FOR NEW CONTRACTORS

- By Admin

- •

- 19 Sep, 2018

- •

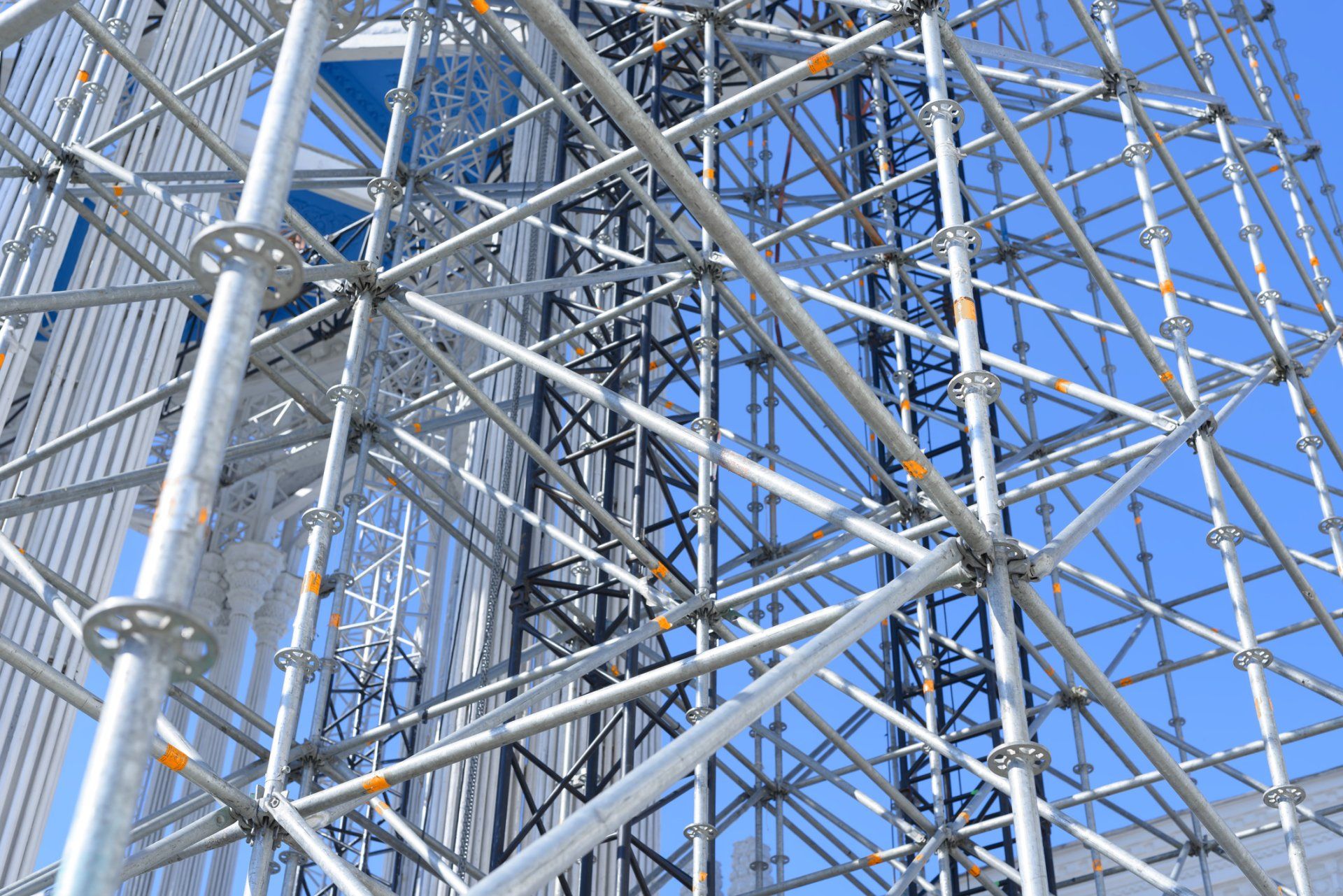

Dust, debris, paint, and harmful substances such as asbestos are common byproducts in construction sites. You can minimize environmental pollution caused by these substances and also install a safety barrier by encapsulating a building. While several types of encapsulation materials are available, shrink wrap outperforms many of these options.

Read on to learn more about using shrink wrap to protect your scaffold and construction project.

SHRINK WRAP BASICS

Shrink wrap is a low-density polyethylene plastic material with many uses, including containing buildings under construction. Different kinds of shrink wrap are available, but the type used to encapsulate scaffolding is usually thicker to ensure robust and long-lasting encapsulation.

The two forms of scaffolding sheets include traditional sheeting and shrink wrap sheeting.

Traditional Sheets

In the recent past, contractors mostly used traditional sheets to cover scaffold. These sheets are made from plastic and are still useful in smaller construction projects.

With traditional scaffolding sheets, construction workers wrap the strips of sheet around scaffolding and then attach each sheet to the next one using bungee strings.

Traditional scaffolding sheets have their own advantages. However, this method of encapsulation leaves spaces in between the individual sheets through which dust, debris, and weather elements can penetrate.

Shrink Wrap Sheets

The use of shrink wrap to contain scaffolding involves using heat from a heating gun to join individual sheets. This joining process eliminates the gaps that typically appear in traditional scaffolding sheets. As such, shrink wrap is more weatherproof and less prone to tearing, and the heat-bonding process makes the encapsulation more durable.

Shrink Wrap Installation Rate

Every contractor wants to minimize the amount of time workers take to complete tasks at a construction site. The rate at which you can install shrink wrap on your building's scaffolding will depend on several factors.

Weather

Rainy and windy weather conditions can slow down work at a construction site. Workers will likely take longer to install shrink wrap in inclement weather due to the difficulty of welding wet shrink wrap.

Area

Encapsulating roof scaffolding is more challenging than doing the same for wall scaffolding. Accessing and moving around the roof can be comparably more time-consuming and resource intensive.

Shape

The shape of the scaffolding will also determine how long workers will take to encapsulate the building. Complex scaffolding with numerous protrusions will require plenty of maneuvering and can take more time to shrink-wrap.

Expertise

If workers have the skill and relevant experience, they can install shrink wrap faster. Alternatively, you can ask your shrink wrap provider to install the encapsulation. Many providers have a team of experienced installers who can get the job done professionally.

These factors will also affect the overall cost of installing scaffolding shrink wrap.

Shrink Wrap Installation Considerations

Shrink wrap is an excellent material for encapsulation, but you should assess the suitability of using this containment method for your project.

Some important considerations to make include:

- Type of project: Shrink wrap is more suitable for large construction projects that require robust encapsulation solutions

- Cost: Larger projects may justify the cost of shrink wrap. Shrink wrap services may also make more economic sense if you have regular clients that require such services

- Training: You could hire a professional shrink wrap installation company or train your workers to install shrink wrap. Consider whether you are prepared for the time and resource investment required to train workers to acquire this new skill.

These considerations will help you control construction costs and ensure true ROI if you opt to use shrink wrap for scaffolding encapsulation.

When looking for encapsulation solutions, work with a reputable shrink wrap specialist who can provide quality materials and trustable installations.

You can trust the experts at Pacific Scaffold Company to deliver quality shrink wrap services customized to your needs. Call us today to learn more about our solutions.

Share

Tweet

Share

Mail

1340 12th St. Oakland, CA 94607

CA LIC# 292509

Content, including images, displayed on this website is protected by copyright laws. Downloading, republication, retransmission or reproduction of content on this website is strictly prohibited. Terms of Use

| Privacy Policy