SCAFFOLDING SAFETY: YOUR RESPONSIBILITIES TO KEEP EMPLOYEES SAFE

Admin • May 22, 2018

Up to 2.3 million employees in the construction industry work on scaffolds. Each year, 4,500 injuries and about 60 scaffold-related deaths occur. Understanding and complying with Occupational Safety and Health Administration (OSHA) safety requirements is a crucial step toward ensuring employee safety at construction sites.

Here are some of the things you should do to keep your employees safe when they are working on scaffolds.

Secure the Platforms

Scaffold platforms should be as compact as possible. The space between the vertical panels and the platform should not exceed 1 inch. If the side brackets create a wider space between the vertical panels and the platforms, this space should not be more than 9 inches. Other scaffold safety measures are specific to the type of scaffolding being used.

Supported Scaffolds

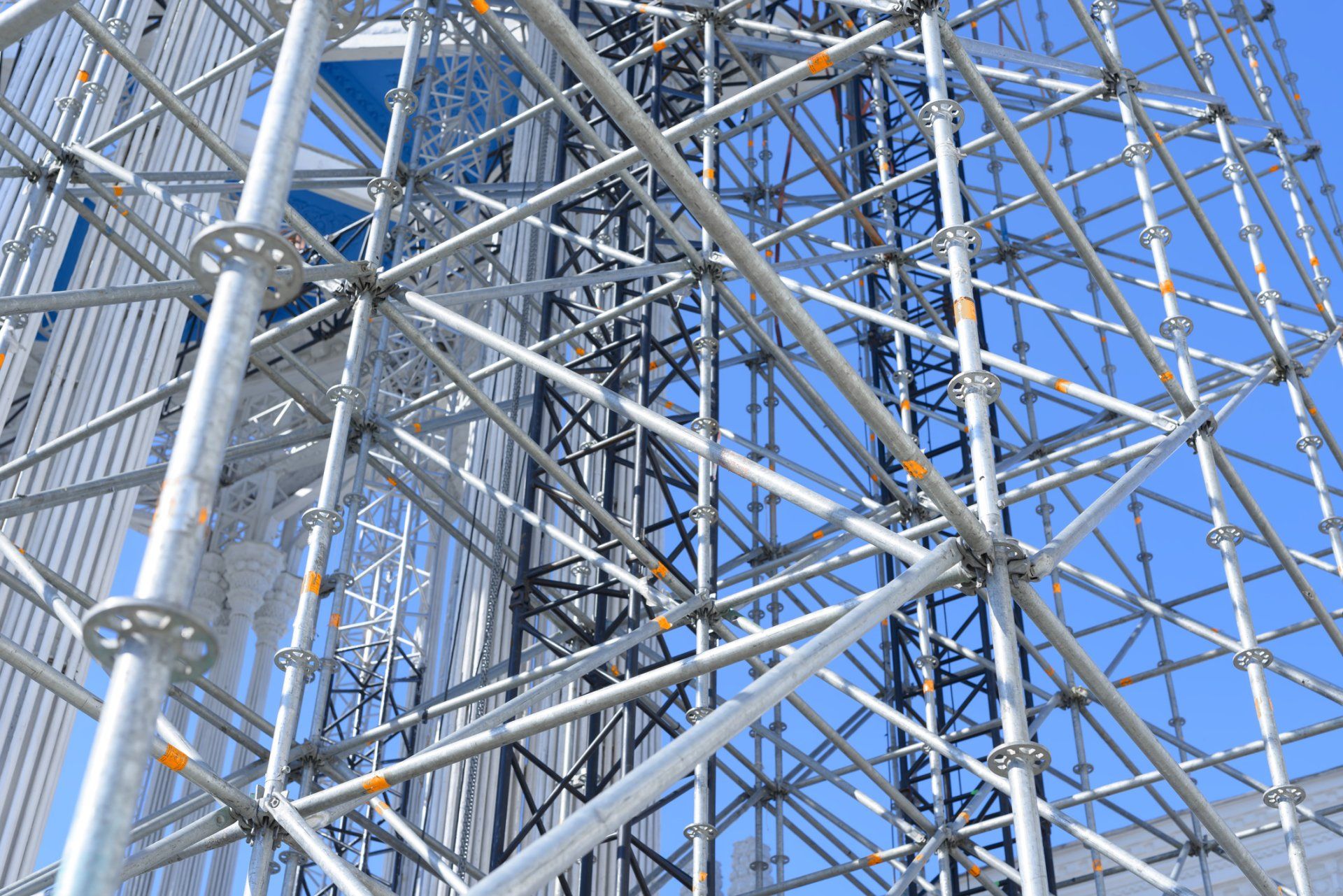

Supported scaffolds are buttressed by rigid components such as vertical panels, poles, side brackets, legs, frames, and posts. Be sure that these components are sturdy and adequately reinforced to protect the platform from swaying and possible collapse.

Suspended Scaffolds

A suspended scaffold features platforms that are suspended from an overhead structure by non-rigid components such as ropes. Ensure that support components are attached to surfaces that can support at least four times the load placed by the scaffold at the rated load of the rope or at least one and a half times the load placed by the scaffold when operating at the hoist's stall capacity, whichever is greater.

Prohibited Scaffolds

OSHA standards strictly prohibit the use of lean-to and shore scaffolds. Do not allow employees to work on scaffolds covered in slippery substances such as water, ice, or snow.

Understand Load Capacity

Understand Load Capacity

OSHA requires that each scaffold and related component be strong enough to support its weight. Ensure that the scaffolds can support at least four times the weight of the maximum load that will be applied. Find a qualified scaffold installation company to set up the scaffolds on your construction site.

Protect Employees From Falling Objects

To your employees safe from falling objects, have a scaffold installation company install protective structures such as barricades, catch platforms, guardrails, toe board screen, debris nets, or canopies. Ensure that all employees wear appropriate work gear including hard hats.

Conduct Regular Inspections

Inspect all scaffold connections to ensure that all structures can support the imposed weight. Ensure that suspension scaffolds are tied to prevent swaying and displacement. Examine hoists before each work shift to ensure they are in good shape. Assess the viability and safety of fall protection systems for workers who are erecting or disassembling supported scaffolds.

According to OSHA requirements, only a competent person should inspect scaffolding. A competent person can identify existing and potential hazards and is authorized to take action to eliminate any danger at the work site.

Provide Regular Employee Training

In addition to providing safe working conditions for your employees, you have a responsibility to train them as part of OSHA requirements. Training should include proper use of scaffolds, proper handling of materials on the scaffolding, the risk of falling, fall prevention using a personal fall system, electrical hazards, falling object hazards, and safe load-carrying capacities.

Only a qualified scaffold safety professional can train employees to identify different scaffolding hazards and ways to mitigate these hazards. OSHA defines a qualified person as one who can demonstrate problem-solving abilities and competency on scaffolding work. Find a professional person who has relevant certification, a recognized degree, experience, and/or extensive knowledge in scaffolding to train your employees.

If you are looking for a competent scaffold installation company that will help you comply with OSHA standards, get in touch with Pacific Scaffold Company

today. We'll be happy to discuss your project and to provide expert advice and estimates.