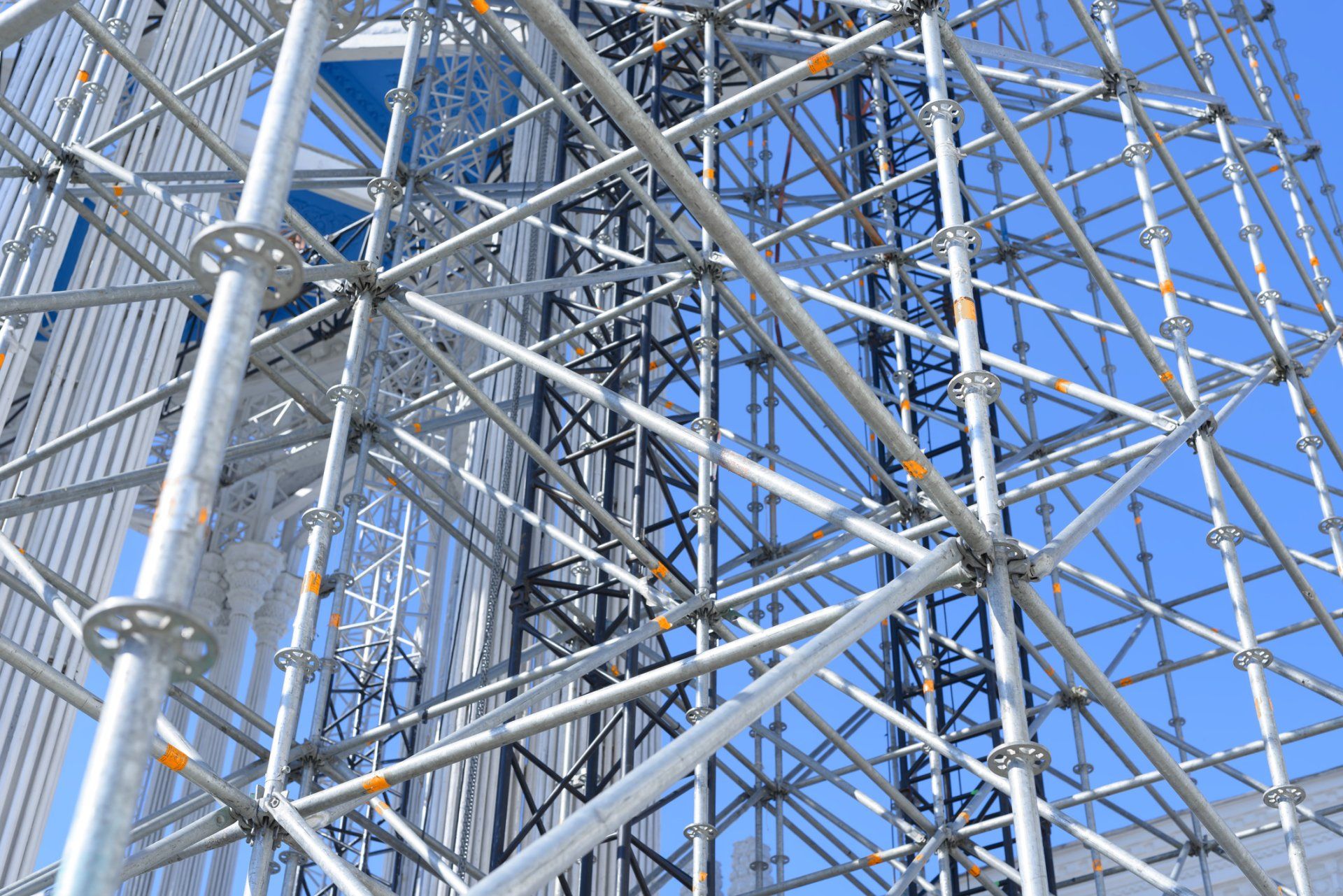

3 TIPS TO EXTEND THE LIFE OF YOUR SCAFFOLDING

Safety should always be a number one concern when it comes to utilizing equipment at a job site, and this includes when you are using scaffolding. There are reportedly 2.3 million constructions workers who work on scaffolds, so it is very important that these workers are kept safe. According to the Bureau of Labor Statistics, there are roughly 4,500 injuries and more than 60 deaths annually related to scaffolds.

While it is true that improving the knowledge of scaffolding safety can reduce the risk of injury and death on scaffolds, another way to help prevent scaffolding injuries is for employers and companies to maintain their scaffolding properly. Here are three tips that will help you properly maintain your scaffolding while also extending its life.

Tip #1: Replace Worn Out Parts

You can purchase top-of-the-line scaffolding from the get-go, but you are still going to have to deal with parts that wear out eventually. This is simply something that happens with every type of equipment. This is the nature of running a construction site that is dealing with constant traffic and heavy loads of materials.

It is crucial that you never rely on scaffolding parts that are not 100 percent in compliance. If you see a part that is showing signs of fatigue, such as splitting, bending, or any other signs of wear and tear, it is imperative that you repair or replace the part immediately. This is because the safety of your workers and others in the area can no longer be guaranteed.

Tip #2: Use WD-40 or a Similar Product to Prevent Rust and Deterioration

All moving parts on your scaffolding need to be fully functional at all times. To ensure that this is the case, you should consider purchasing some WD-40, or a similar product, to use on nuts, bolt threads, and other removable and moving parts. It will help keep these parts properly lubricated and prevent rust and corrosion.

In addition, this specific process will help to maintain overall efficiency, improve safety, prevent unnecessary delays, and shutdowns during projects, and ensure your scaffolding lasts longer.

Tip #3: Clean Scaffolding Before Storing

When your scaffolding is not in use, it is important that it is not simply left out in the weather elements to be damaged. At the same time, you want to be careful when you take apart the scaffolding and go to store the materials to avoid unnecessary repairs and/or replacements when it is time to set the scaffolding back up.

To begin, you will want to clean the scaffolding thoroughly. You can simply use a garden hose or a power washer to rinse the scaffolding down. You will want to use a rag to wipe it down to help prevent rust. If there is a lot of build-up of mud, stucco, paint, or something else, you may need to utilize a sander to remove the accumulated debris. The cleaning process ensures that no contaminants are left behind on the equipment to do damage.

Next, as you begin to break down the scaffolding, make sure that you keep all the pieces organized. Keeping the pieces organized will ensure that everything is easily located and put back together when the equipment needs to be used again in the future. When you store the scaffolding, make certain that you have a large enough area that can house all of the scaffolding equipment together, including the poles, planks, bolts, and screws. This will minimize the time spent on the next use.

Following the tips above can help ensure that your scaffolding lasts longer, which will help improve your return on investment (ROI) and improve the safety of your workers. If you want to ensure that you are working with a well-maintained and safely-installed scaffold, contact us

at Pacific Scaffold Company for a quote for your job site.